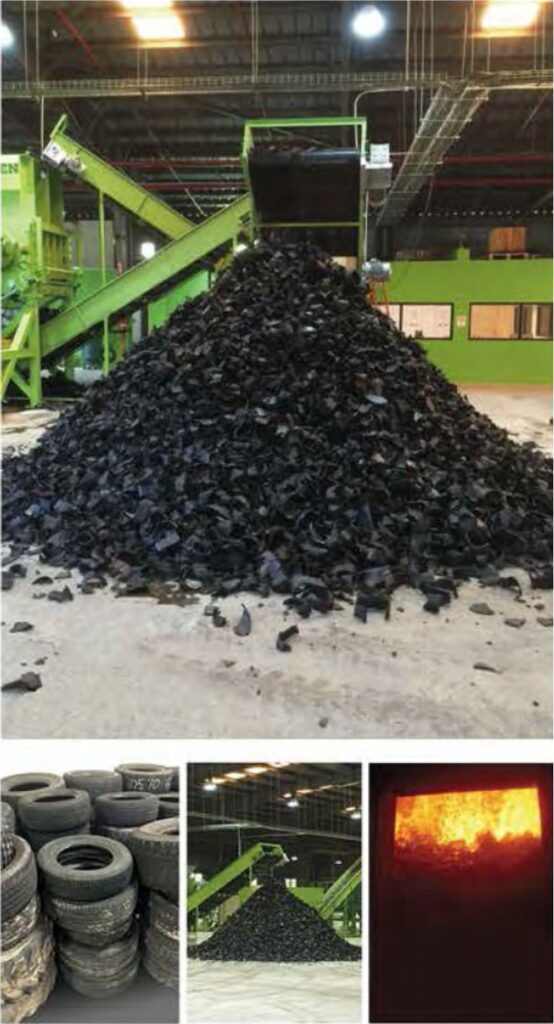

TDS (Tire Derived Shreds)

Tire-derived fuels (TDF) are composed of shredded scrap tires from passenger cars and trucks

TDS & TDF Shreds

Tire-Derived Shreds (TDS) are the initial byproducts derived from the shredding process of scrap tires, encompassing whole tires or pre-cut pieces entering and exiting a primary shredder. This primary cut yields shreds typically ranging between 2 to 6 inches in size, with the flexibility to vary in size after the initial cut. The option for recirculating the first shreds allows processors to tailor the output to smaller sizes as needed.

These TDS shreds consist of a mixture of steel, fiber, and rubber components. Processors have the option to sell these shreds to interested buyers or choose to continue processing for further refinement and additional material outputs.

The versatility of TDS shreds is reflected in their diverse range of applications, serving purposes from being a valuable fuel additive to finding use in various civil engineering projects. The labeling of TDS shreds can vary based on their intended application; for instance, those destined for burning and energy production are commonly known as “TDF” or “Tire-Derived Fuel,” highlighting their high BTU heating value. The adaptability and multifaceted uses of TDS shreds make them a valuable resource in sustainable material management and recycling practices.

TDS Processing:

- Scrap Tires Reduced to 2”-6” shreds.

- Takes 100 passenger car tires to make one ton of TDS.

- TDS contains steel, fiber, and rubber in shreds.

- TDS can be processed further removing steel & fiber.

TDS Benefits:

- Cost Effective Solution to Native Materials

- Efficient Insulation and Vibration Properties

- Suitable for both small and large-scale projects

- Diverts Tires from Landfills and Environment

TDS Markets:

- Cement Manufacturing (TDF)

- Pulp and Paper Facilities (TDF)

- Civil Engineering Applications (TDA)

- Other Electric and Industrial Industries

PRODUCT INQUIRY

- Youtube