Tire Rubber Powder

Premium Rubber Powder Production for Eco-Friendly Solutions

Rubber Powder Production

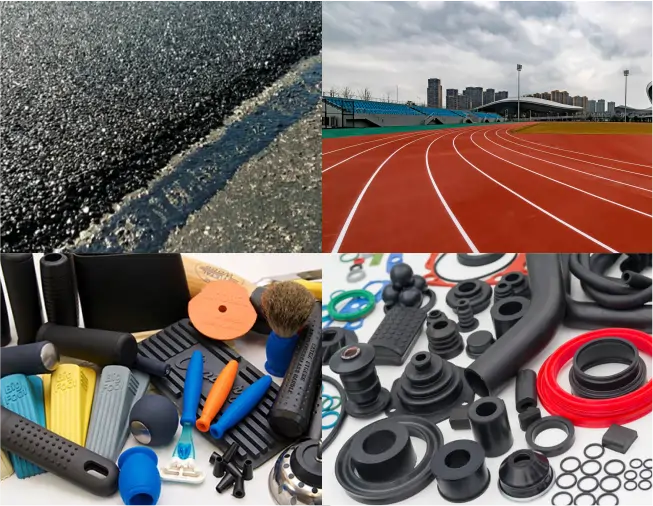

Rubber Powder marks the culmination of ambient tire recycling, where crumb rubber undergoes a meticulous grinding process, resulting in a pristine powder devoid of steel and fiber. This versatile powder finds application in injection molding products, coatings, roofing materials, and various asphalt solutions.

Typically ranging from 400 to 74 microns (0.400 to 0.074 mm) in size, Rubber Powder boasts the flexibility to be seamlessly integrated into new or existing formulations across different polymers and end products. Serving as industrial feedstock, this material meets stringent specifications and undergoes a sophisticated process, ensuring its compatibility with diverse manufacturing and industrial processes. The intricate reduction of scrap tires yields fine granules, devoid of wire and fiber, catering to specific applications like automotive parts, paints, and coatings that necessitate a finer feedstock size.

Diverse Applications of Rubber Powder

Asphalt Modification: The incorporation of rubber powder into asphalt mixtures enhances overall performance by improving elasticity, minimizing cracking, and bolstering resistance to temperature fluctuations. Widely employed in road construction, this application results in road surfaces that are not only more durable but also exhibit prolonged longevity. Additionally, the use of rubber powder can enhance the forgiving nature of asphalt, particularly in the event of a motorcycle accident, trip, or fall.

Sports Surfaces: Rubber powder plays a crucial role in the composition of artificial turf and rubberized playground surfaces. Its inclusion contributes to superior shock absorption, mitigating the risk of injuries during various sports activities. Recognized for its resilience and weather resistance, rubber powder proves to be an excellent choice for outdoor recreational areas. Importantly, there is no scientific evidence supporting concerns about potential health threats to children from toxins in car tires used in rubber powder surfaces.

Manufacturing of Rubber Products: Renowned for its versatility, rubber powder serves as a valuable raw material in the production of various rubber-based goods. Manufacturers frequently utilize it in crafting items such as rubber mats, gaskets, seals, and flooring materials. The incorporation of tire rubber in the manufacturing process not only diversifies the range of produced goods but also contributes to a sustainable approach by reducing reliance on virgin rubber.

PRODUCT INQUIRY

Rubber Powder Atributes

Rubber Powder is the final result of ambient tire recycling. At this stage, crumb rubber is ground down into a clean powder form with virtually all steel and fiber removed. Rubber Powder has numerous secondary uses from injection molding products, coatings, roofing materials and various asphalt applications.

Rubber Powder is typically found in 400 – 74 microns (0.400 – .074 mm) in size. This micron-size material has the advantage of being incorporated into new or existing formulations for various polymers and finished products.

Rubber Powder Processing:

- Crumb Rubber material typically reduced to 400 microns (0.400 mm) powder or smaller is Rubber Powder

- On Average, 5 to 8 pounds of rubber powder can come from one passenger car tire Rubber Powder sizing is comparable to the consistency of flour

Rubber Powder Markets:

- Molded Plastic Applications

- Sealant and Paint Additive Rubber

- Modified Asphalt Thermo Plastics Applications

- Geo-Membranes

- Other Extruded Products and Rubber Mixtures

Rubber Powder Benefits:

- Stress absorbing properties for asphalt application

- Performance and Durability

- Incorporated into multiple polymers and products

- Diverts Tires from Landfills and Environment

- Youtube